Fluorocarbon PVDF color coated aluminum coil

Key words:

Classification:

Al-Mg-Mn color coated aluminum coils

Hotline:

Fluorocarbon PVDF color coated aluminum coil

Graphic Details

Al-Mg-Mn color coated aluminum sheet in coils

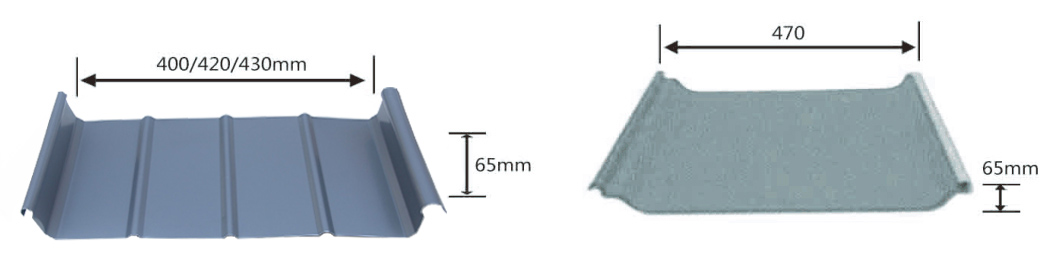

Al-Mg-Mn color coated aluminum sheet in coils are mixed alloys of aluminum, magnesium and manganese ,Alloys of the Al-Mn-Mg are high quality roofing material, widely used in building decoration because of good intensity,excellent weather-proof durability,high erosion resistance,easy for processing more than 30 years.The coating of aluminum sheet is strictly according to customer requirements. RAL color and customized color are available. Paint from U.S. PPG , the Korea KCC and other famous paint suppliers and the coating property are in standard of AAMA2605.

Application

Alloys of Al-Mn-Mg are widely used for steel structure plants, gymnasium Metal roofing, airport metal roofing, theatre metal roofing, high-class plants metal roofing, landmarks, civil construction, etc

Characteristic

·Secure and stable system structure

·Infinite application potential

·Perfect performance of reducing noise

·Fantastic thermal insulation and fire-proofing

·Durable and valuable roofing system

·Excellent Lighting protection

Color coating and printing line

Color coated aluminum sheet in coils has the characteristics of long service life, light weight, excellent surface effect and high recycling value, and has good economic benefits to meet the urgent demand of the current social economy and environmental protection development. Our factory’s aluminum color coating production line uses Germany's Siemens complete line control system, and the core painting process uses the world's most advanced German roll coating technology and twice-coated, twice-hot air-curing coating technology to accurately control coating thickness and curing quality. The color aluminum adopts neutral treatment agent, roller coating treatment and hot air rapid drying process in the chemical treatment process, which is different from the ordinary dip coating chemical treatment method, which effectively eliminates environmental damage.Moreover, the surface treatment is carried out with advanced chromium-free treatment liquid to meet strict environmental protection requirements at home and abroad.During the curing process of the color coated aluminum plate surface coating, the volatile components can be recycled and utilized for the second time, and equipped with an advanced VOC defluorination system to improve the utilization rate of heat energy while achieving zero emissions, and absolutely eliminate environmental pollution.

Previous Page

Next Page

Previous Page

Polyester PE color coated aluminum coil

Next Page

More products

Leave A Message

Online search

CopyRight © 2019 Zouping Zenwin Aluminum Technology Co., Ltd. 国际站建设:中企动力 淄博 外贸Google推广 SEO